Mold Reconditioning

From material build up to dents in the surface, over time, the manufacturing molding process can cause wear on your molds. This only leads to unwanted part defects and low-quality production of plastic products.

From material build up to dents in the surface, over time, the manufacturing molding process can cause wear on your molds. This only leads to unwanted part defects and low-quality production of plastic products.

At Monroe Mold, we understand that all molds eventually wear out, but through our mold reconditioning process, we can help you get the extra life out of your molds. Through our systematic approach, we evaluate your molds and determine the proper course of action to bring them back to like-new condition. Remembering the type, fit, relational position of components, and the sheer volume of tooling in some molds can be overwhelming enough without adding confusion about where you are in the process of mold repair. From start to finish, we ensure nothing is overlooked. Not only will your molds be back up and running, they will be back to producing bottles that meet and exceed your expectations.

Mold Repair

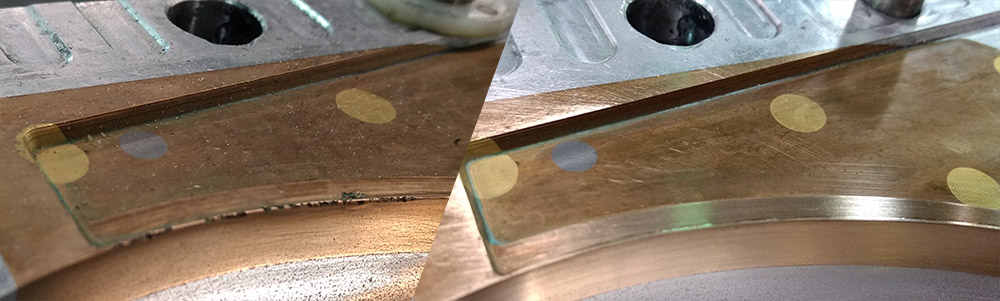

To keep your molds running at full production, they need to be properly maintained and repaired. By conducting periodic mold maintenance and repair, you can improve production, reduce downtime and lower the overall cost of owning the tool. Typical mold repairs include building up worn or damaged surfaces, filling in small voids, repairing parting lines or thin walls, fixing cracks and accommodating engineering changes or fixing mistakes.

At Monroe Mold, we are an all in one plastic mold facility. Our state-of-the art repair services will help you get back up and running in no-time. With over 30+ years of experience in extrusion blow molding, tooling, and assembly, we have the expertise to repair and maintain plastic molds in house. Being an expert of plastic blow molding, we know molds inside and out, so who better to repair or maintain them when needed? If your operation lacks the time or capacity to execute this step, trust Monroe Mold to provide an efficient, transparent process and unsurpassed quality in our results.

Do you have a blow mold that has not been properly maintained and is no longer in service? If you have a broken mold and think your only option is to build new, think again. We’ve repaired molds with every conceivable problem. We’ve seen it all.

If you have a plastic extrusion mold that has been poorly maintained or damaged, starting over is not your only option. Even if your mold has extensive damage and has exceeded its warranty, there may be a quick and easy fix. We may weld the mold to rebuild broken down areas. Wear surfaces can be rebuilt, and pinch edges can be re-worked. A rejuvenated blow mold can provide years of continued service. It can provide thousands or even millions of additional production parts, and savings of thousands of dollars compared to building new. To learn more about our repair capabilities, contact us today at (734)-241-6898.